Contacts:Yunhua Bearing

Tel:0635-2834111

Phone:150 6359 1590 135 6300 5885

Address:Industrial Park, Panzhuang Town, Linqing City, Shandong Province

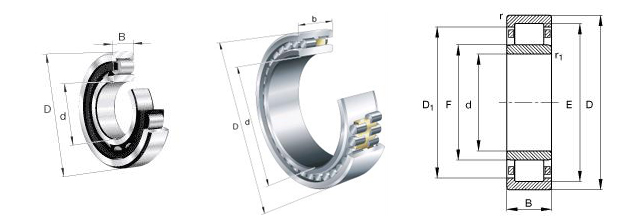

The rolling element of cylindrical roller bearing is a cylindrical roller, which belongs to the separable type of bearing and facilitates installation and disassembly. According to the presence or absence of ribs on the ring, it can be divided into single row cylindrical roller bearings such as N, NU, NJ, NF, NUP, and double row cylindrical roller bearings such as NNU and NN. In addition, there are multiple row cylindrical roller bearings. Cylindrical roller bearings generally use copper alloy solid cages or engineering plastic cages. When the speed is low and the load is high, they can be designed as a full roller structure without cages.

The cylindrical roller bearing is in line contact with the raceway, with a large load capacity and mainly bears radial loads. The friction between the rolling element and the collar edge is small, suitable for high-speed rotation, and requires high coaxiality during use. Cylindrical roller bearings without retaining edges on the inner or outer rings can move relative to the axial direction, so they can be used as free end bearings. A cylindrical roller bearing with double ribs on one side of the inner and outer rings, and a single rib on the other side of the ring, which can withstand a certain degree of unidirectional axial load.

N. NU type

The outer ring of the N-type bearing has no ribs, while the inner ring has ribs on both sides, allowing for axial displacement between the shaft and the bearing seat in both directions. The outer ring of the NU type bearing has ribs on both sides, while the inner ring has no ribs. It is also possible to allow displacement between the shaft and the bearing seat in both axial directions, so this type of structure is suitable for use as a floating end bearing.

NJ, NF type

NJ type bearings have retaining edges on both sides of the outer ring and retaining edges on one side of the inner ring. Capable of withstanding a certain amount of unidirectional axial load, the NF type outer ring has retaining edges on one side and the inner ring has retaining edges on both sides. It can also withstand a certain amount of unidirectional axial load, therefore, this type of structure is suitable for use as a unidirectional axial positioning bearing

NUP type

The NUP type bearing has retaining edges on both sides of the outer ring, a fixed single retaining edge on one side of the inner ring, and a separable flat retaining ring on the other side, which can withstand a certain amount of bidirectional axial load.

NN, NNU type

The outer ring of the NN type bearing has no retaining edges, while the inner ring has retaining edges on both sides and a middle retaining edge in the middle, which allows for axial displacement between the shaft and the bearing seat in two directions. The outer ring of NNU type bearings has retaining edges on both sides and a middle retaining edge in the middle, while the inner ring has no retaining edges. It is possible to allow displacement between the shaft and the bearing seat in two directions in the axial direction. Therefore, this type of structure is suitable for acting as a floating end bearing.

Product Features

The inner or outer ring can be separated for easy installation and disassembly;

Large radial bearing capacity, suitable for withstanding heavy and impact loads;

Low friction coefficient, suitable for high speeds, with limit speeds close to deep groove ball bearings;

N-type and NU type can move axially and be used as free end support;

The machining requirements for shafts or seat holes are high, to prevent relative deviation and avoid contact stress concentration.

Main areas

Large and medium-sized electric motors, locomotives and vehicles, machine tool spindles, internal combustion engines, generators, gas turbines, reducers, rolling mills, vibrating screens, and lifting and transportation machinery.